Video

1 / 6

Mold Designing High Quality Stamp Metal Mould Parts

| Model No. : | plastic injection Mould 3 |

|---|---|

| Brand Name : | intertech |

| Brand Name : | Intertech (Taiwan) |

Taipei City, Taiwan, China Taiwan

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

High Quality Metal Mould Form Shape Mode Figure Schimmel Formen Mold

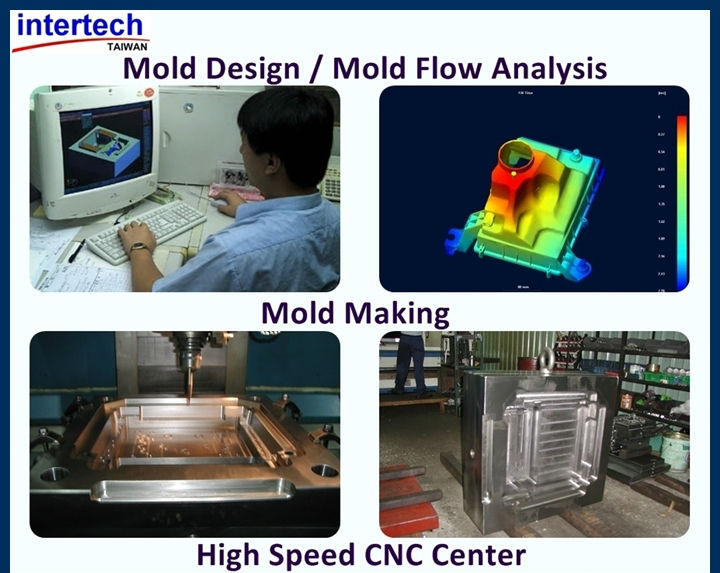

Plastic injection Mould designing - Intertech(Taiwan)

Intertech Machinery, Inc. works collaboratively withany foreign countries to analyze buys’ needs, come up with solutions, and exceed expectations with high-quality products delivered on time. Our experienced design consultation, technical assistance, and production support help our customers to accomplish their business goals. We take an enormous interest in our customer’s needs evidenced by our partnership work ethic. When you work with our professional team you’ll obtain the best finished products in the most economical fashion.

We provide a OEM solution for customers in a wide range of industries. Our complete design and manufacturing process includes part modeling and mold design, prototyping, tool sourcing, production planning, sample verification, process control, decorating, secondary processing, and packaging.

Most importantly, here we are in Taiwan, who has undoubted manufacturing and reasonable price compared with other unreliable products in other countries.

In short, we are both a professional mold maker and molder, with more than 25 years experience in Taiwan. We’ve done many plastic projects for our clients from all over the world.

Please provide your specified demands and your technical data (2d, 3d drawings or samples), so that we can study for it, understand the whole structures, and go further steps.

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

|

Plastic materials: |

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

|

Other materials: |

Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

|

Quality: |

ROSH and SGS standard |

|

Feature: |

Non marking and Non flash |

|

Size: |

According to your drawing |

|

Color, Quantity, Unit price, Tooling cost, Tooling size: |

To be discussed |

|

Mold structure: |

Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

|

Mould Base: |

HASCO standard, European standard, World standard |

|

Mould Base Material: |

LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

|

Surface Finish: |

Texture (MT standard), high gloss polishing |

|

Finish: |

Mirror finish etc. |

|

Cavity / Core steel: |

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

|

Cavity: |

Single cavity, Muti Cavity, based on customer’s requirement. |

|

Hot / Cold Runner: |

HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

|

Mould Life: |

1,000 to 1,000,000 shots (according to your working environment) |

|

Design & Program Softwares: |

CAD, CAM, CAE, Pro-E, Solid works…etc. |

|

Equipments: |

High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

|

Package: |

Standard exported wooden box packed, fumigation process (upon required) |

|

Mold building lead time: |

T1, 40~50 days, parts measurement report (upon required). |

|

Annual production: |

250 sets of mold |

About Us:

In short, Intertech (Taiwan) provides an extensie integrated operational ability from design to production of molds 100% made in Taiwan.

With the performance level in Taiwan, we satisfy our world customers with the best value of mold making workmanship: customer design service; prototyping; mold making; manufacturing process control; reverse engineering; customer molding & assembly...etc.

We manufacture plastic injection molds, die-casting molds, silicone rubber molds, liquid silicone rubber molds, LSR molds, rubber molds, press molds and hot runner molds (MoldMaster, MasterFlow, LKM, Incoe systems...etc).

We are particularly specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high gloss polished molds, interchangeable core molds, hot compression molds, 2-component injection molds, and pilot molds for small series production...etc.

Video

Taipei City, Taiwan, China Taiwan

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier