Video

1 / 6

Sand casting shot blasting QT450 profile flanges

$8.80

≥50 Others

$8.70

≥2000 Others

$8.60

≥5000 Others

Options:

- HY-819

| Brand Name : | HY |

|---|---|

| Condition : | New |

Taizhou, Jiangsu, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Product description

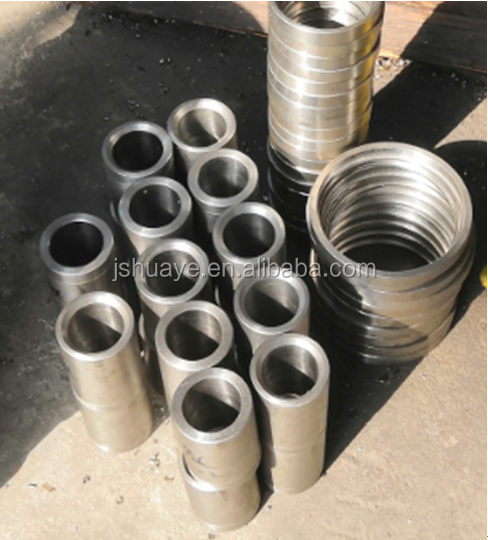

Customized sand casting shot blasting QT450 profile flanges and heat treatment furnace fixtures for heat treatment industry

Product description

Heat treatment fixtures kit of heat resistant steel; all kinds of heat resistant steel ;castingstraight radiant tubes, W-type tubes, U-type tubes,electric radiant tubes

Application

the various radiant tubes are used in the furnaces for steel mills, like CAL(continuous annealing line),

CGL(continuous galvanizing line).

Process

Centrifugal casting, precision casting and machining.

Materials Standards

ANSI, ASTM, ASME, DIN, GB

Materials: High nickel and high chrome heat resistant alloys, cobalt base alloys, like HU, HT, HK, HP, HW, 24/24NbTiZr, 50Cr/50Ni (2.4813), 1.4865, 1.4849, 1.4848, 1.4410, 1.4059, 1.4841, 1.4845, 1.4852, 2.4879 or as per customer's requirements

Quality Control

We carry out very strict quality control from raw material to each step of the process, until the finished product is dispatched. To make sure the highest quality possible, each test is carried out strictly with our in-house testing facilities. The most generally used methods of testing given below:

Chemical analysis by Spectrometer

Mechanical tests in Normal and High temperature.

Ultrasonic, X-ray, Dye Penetrant Test.

Boroscope;Microscope ; Pressure tests,etc

Advantages

More than 30 years of professional experience and continuous R&D efforts enable us to offer better custom design and engineering advice.

Use only new raw material like nickel plate, chrome iron, cobalt, ferrotungsten to guarantee physical property and increased service life of our castings.

Owned in-house production and inspect facility to guarantee the best quality.

Experienced workers for foundry, machining and welding guarantee excellent quality and prompt delivery

Precision machining

Lathes, milling machines, drill presses, Boring machines, CNC grinding machines, etc

Package

packed by seaworthy wooden case or according to buyers’ request.

Delivery time

according to the quantity of the P.O. usually25 days after the order is confirmed.

Service

We can make radiant tubes, furnace rollers and other dewaxing or sand casting products according to customers’ DRAWINGS.

Main Features

Used in petrochemical, metallurgical and heat treatment industries etc.

The followings are photos for our factory and stainless steel casting products:

1. Q: How To give inquiry ?

A: Step 1, please tell us what weight ,dimension, material do you need please;

Step 2, Better help to provide the drawing with above-mentioned details please;

Step 3, when we have enough details, we may quote accordingly;

2 . Q: When will make delivery ?

A: Delivery Time

-Sample Order: 15 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 40 days after receipt of the deposit.

3. After-sales Service

1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

4. Payment

T/T, Western Union, Moneygram ,cash.

5. Transportation

Transported by DHL, UPS, EMS, Fedex,Air freight. sea freight.

6. Do you support drop shipping?

Yes,your drop shipping is aviable.

Video

Taizhou, Jiangsu, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier