Video

1 / 6

Circular blade Tungsten Tape Rewinder Carbide Cutter Blade

$25.00

≥10 Others

$20.00

≥50 Others

Options:

- Circular Blade For Tape Rewinder

| Brand Name : | LLY PACK |

|---|---|

| Marketing type : | Ordinary Product |

Foshan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

In the world of tape processing and converting, precision and efficiency are paramount. The Tape Rewinder, Slitter Rewinder, Rewinder Blade, and Dished Knives for Slitter Rewinders are essential components that enable seamless tape handling, slicing, and rewinding operations. These products are designed to enhance the quality of the tape processing workflow while ensuring maximum productivity.

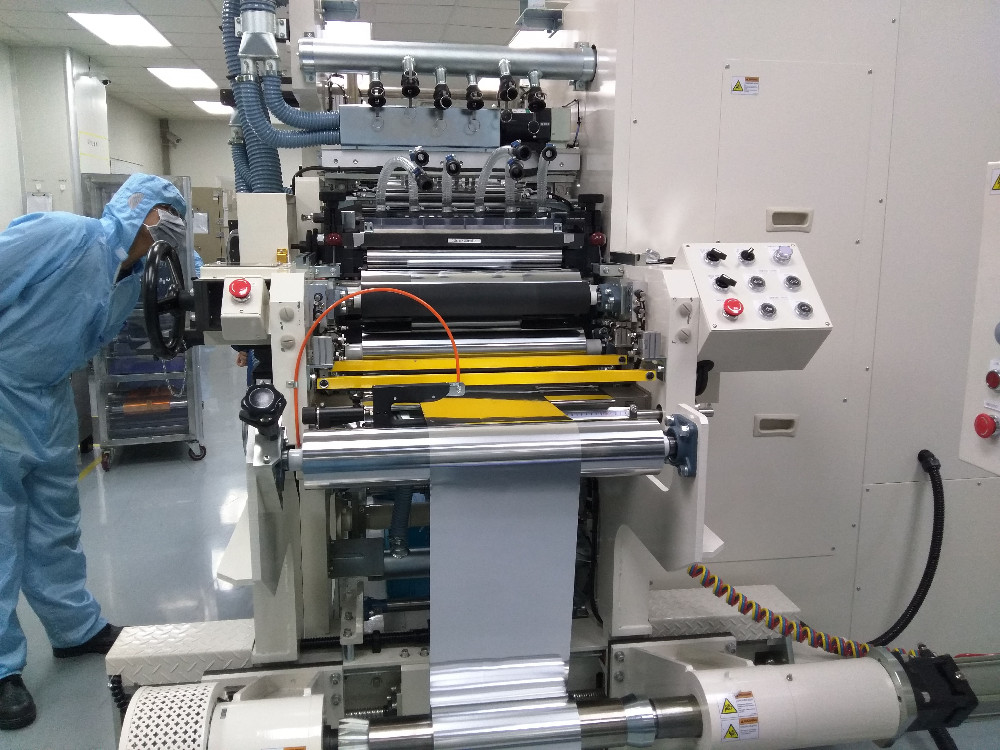

The Tape Rewinder is a vital piece of equipment that allows for the controlled unwinding and rewinding of tape. Its precision-engineered mechanics ensure that the tape is wound evenly and tightly, minimizing any wrinkles or distortions. This ensures that the tape remains in pristine condition, ready for further processing or use. The Tape Rewinder is also equipped with adjustable tension controls, allowing operators to fine-tune the tension to suit specific tape types and thicknesses.

The Slitter Rewinder, on the other hand, specializes in slicing wide rolls of tape into narrower widths. This machine features high-quality blades that are sharp and durable, capable of making clean, precise cuts through even the toughest tape materials. The Slitter Rewinder also incorporates a rewinding mechanism that collects the sliced tape onto separate rolls, ready for further use or packaging.

The Rewinder Blade is a consumable part of the Tape Rewinder and Slitter Rewinder systems. These blades are made from high-grade materials that are both strong and wear-resistant. Regular replacement of the Rewinder Blade ensures optimal performance and extends the lifespan of the equipment. With sharp edges and precise cutting abilities, these blades ensure that the tape is sliced or rewound with minimal damage or loss of quality.

Lastly, the Dished Knives for Slitter Rewinders are specialized cutting tools designed to enhance the slicing capabilities of the machine. These knives feature a unique dished shape that allows for smoother, more uniform cutting action. This not only improves the quality of the cuts but also reduces the risk of tape damage or jamming during the slicing process. The Dished Knives are also easy to install and maintain, minimizing downtime and ensuring maximum uptime for the Slitter Rewinder.

In conclusion, the Tape Rewinder, Slitter Rewinder, Rewinder Blade, and Dished Knives for Slitter Rewinders are a comprehensive suite of products that enable efficient and high-quality tape processing operations. From unwinding and rewinding to slicing and collecting, these products work together to streamline the tape conversion process, ensuring maximum productivity and minimal waste. Whether you're a tape manufacturer, converter, or end-user, these products will help you achieve your tape processing goals with ease and precision.

|

SIZES

OD*ID*T (mm) |

φ110*φ90*1 (TOP KNIFE)

|

|

SIZES

OD*ID*T (mm) |

φ110*φ75*3 (BOTTOM KNIFE)

|

|

SIZES

OD*ID*T (mm) |

φ110*φ90*3 (BOTTOM KNIFE)

|

|

customize

|

Support product customization

|

cutting blades.

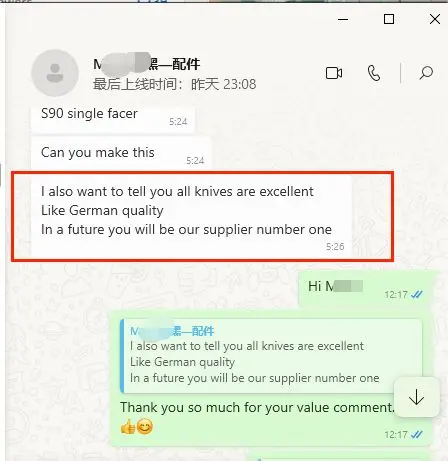

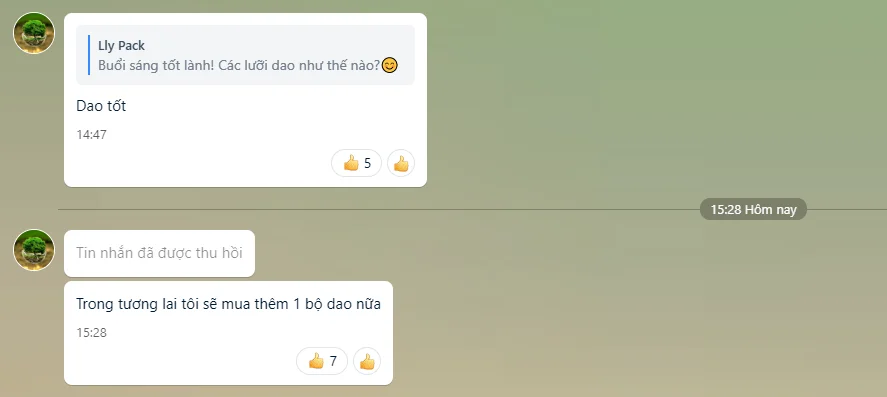

Our brand"Max Cut" is committed to supply the durable and accurate cutting products to our customer without the troubles.

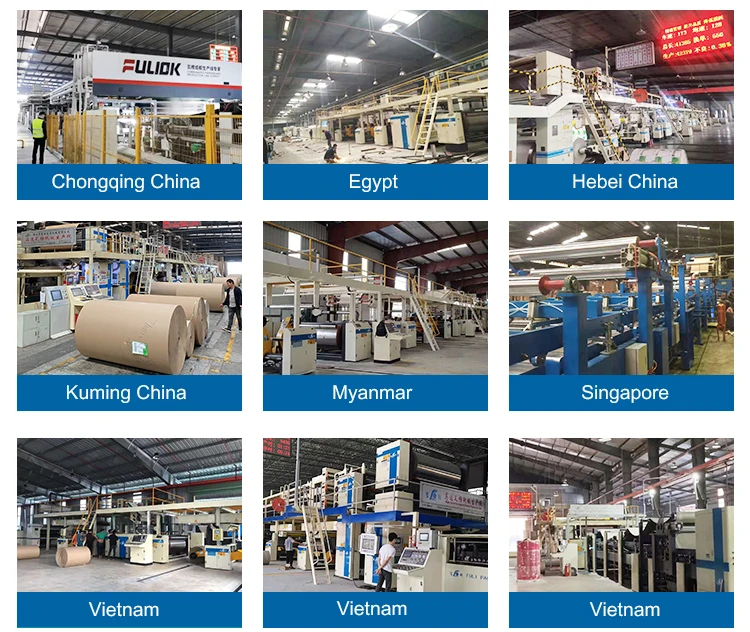

A state-of-the art factory with over 30 sets of high precision CNC machine and the most advanced heat-treatment equipment.

Over 20 years of technical experience, we have been continuously striving for top quality cutting knives. We strictly following our standard quality control.

Corrugated Cardboard & Carton Packaging Industry, Paper Mill, Tissue& Towel converting, Plastic& Flexible Packaging Industry, Food

Packaging, Tobacco Cutting, Fabric& Textile & Leather Cutting, Film& Foil Cutting, Tube Cutting, Metalworking, Wood processing,

Shredder/Crusher Blade and more.

turnaround time.

Please join us for"Win-win cooperation".

Video

Foshan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier