1 / 6

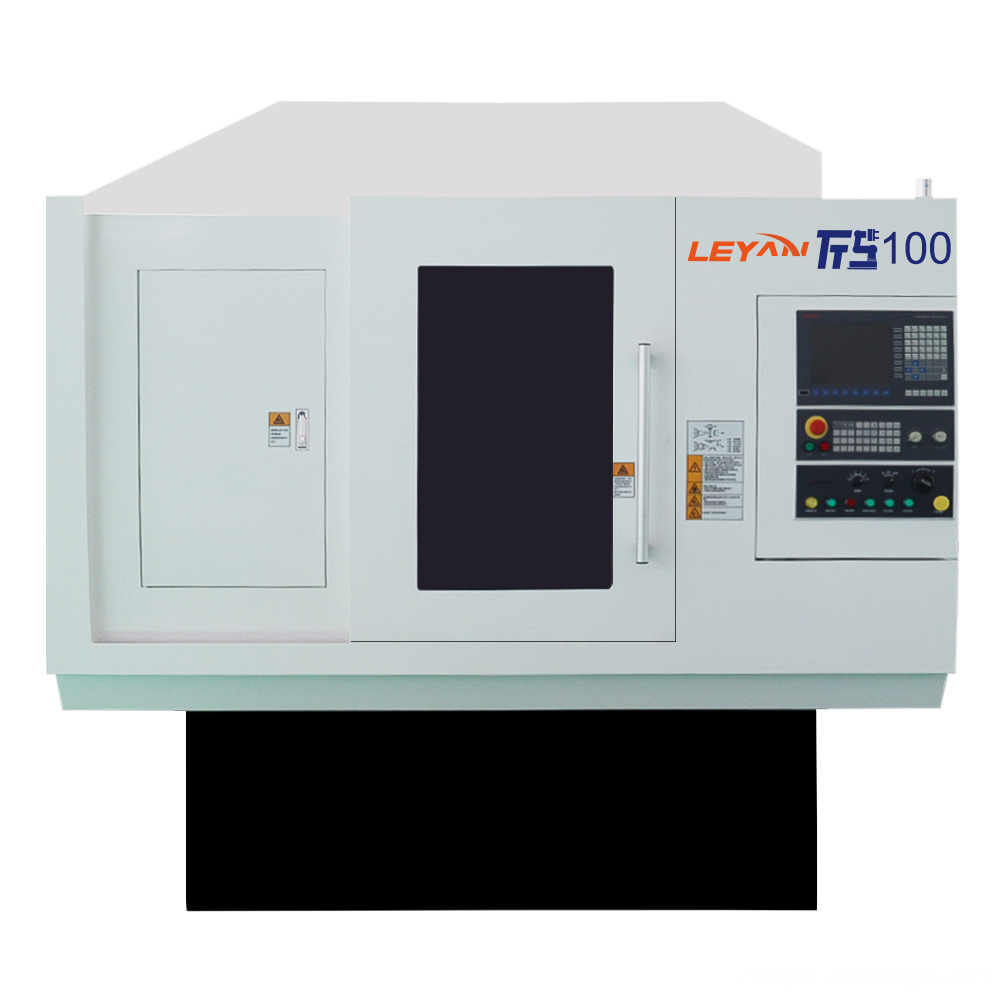

YB100 Seven-axis Quadruple Linkage Gear Hobbing Mahcine

| Model No. : | Gear hobbing machine YB100 |

|---|---|

| Brand Name : | LeyanTTS |

| place of origin : | China |

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

YB100 Seven-axis Quadruple Linkage Gear Hobbing Mahcine

The Automatic Lathe machine tool adopts the high rigidity integral cast iron base, the workpiece Automatic Turning Machine spindle transmission system equipped with the backlash mechanism, the hob frame with the locking mechanism, the servo motor direct link type hob spindle structure design, the overall rigidity is strong, the workpiece spindle and the hob spindle high speed, suitable for high-speed, efficient and high-precision machining. Suitable cutting tools and cooling accessories can realize dry cutting, reduce the coolant, cooling oil mist pollution to the environment and personal injury to the operator, to achieve the goal of clean processing.

By adding the secondary Auto Lathe Machine tool setting accessories (user order), the secondary automatic tool setting of roughed tooth blank can be realized, and the precision rolling of roughed hardened tooth blank can be realized with the use of high-precision carbide hob. By adding deburring accessories can reduce the annoying burr at the cutting end of the gear and improve the quality of the product; According to the characteristics of user parts can be designed and manufactured appropriate automatic loading and unloading system, to achieve fully automatic machining of machine tools.

Specification:

YB100 CNC horizontal hobbing machine

Technical Parameter

unit

parameter

The largest machining diameter

mm

Φ100

The largest processing module

mm

3

Maximum processing length

mm

220

Processing gear range

tooth

3〜999

Hob rotating Angle

°

±45°

The most DaGunDao diameter

mm

80

Hob rod diameter

mm

Φ13mm(or(Φ10、Φ16、Φ22mm)

X, Z axis is fast moving speed

m/min

10

The workpiece spindle

/

/

The highest speed

r/min

1000

The rated torque

N. m

95

Hob main shaft

/

/

The highest speed

r/min

5000

Rated power

Kw

5.5

The X ,Z axis servo motor rated torque

N. m

11

The Y axis servo motor rated torque

N. m

3.5

The W axis servo motor rated torque

N. m

7

The A axis servo motor rated torque

N. m

11

Numerical control system

/

FUNUC

The spindle motor, servo motor

/

FUNUC

Machine tool machining accuracy

/

Grade 6 accuracy GB/T10095-2001 (m W 1.5mm spur and helical gears)

Host machine weight

kg

5000Kg

Machine tool overall dimensions (length x width x height)

mm

2400x2000x2450mm

Main parts brand:

YB100

Product

Brand

place of origin

1

System

FANUC

Japan

2

Spindle motor

FANUC

Japan

3

Spindle motor

FANUC

Japan

4

Bearing

GAMET

Britain

5

Bearing

NSK

Japan

6

Bearing

NSK

Japan

7

Ball screw/Bearing

NSK

Japan

8

Guide way

THK

Japan

9

Ball screw

THK

Japan

10

coupling

KTR

Germany

17

Hydraulic system

CHAO TIAN

Taiwan

19

Electrical component

Schneider

France

20

Chip remover

White Mountain Mechanic

Japan

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier