Video

1 / 3

Sand Casting Automobile Clutch Housing Mould

| Brand Name : | Shinden |

|---|---|

| place of origin : | China |

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Product description

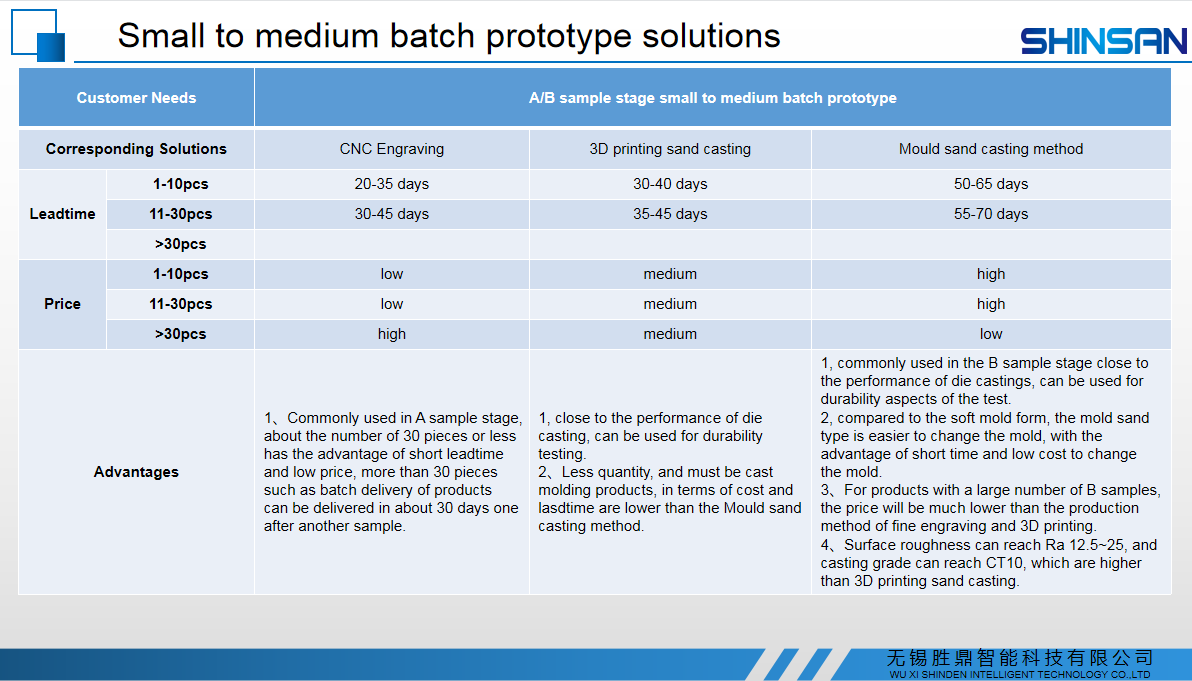

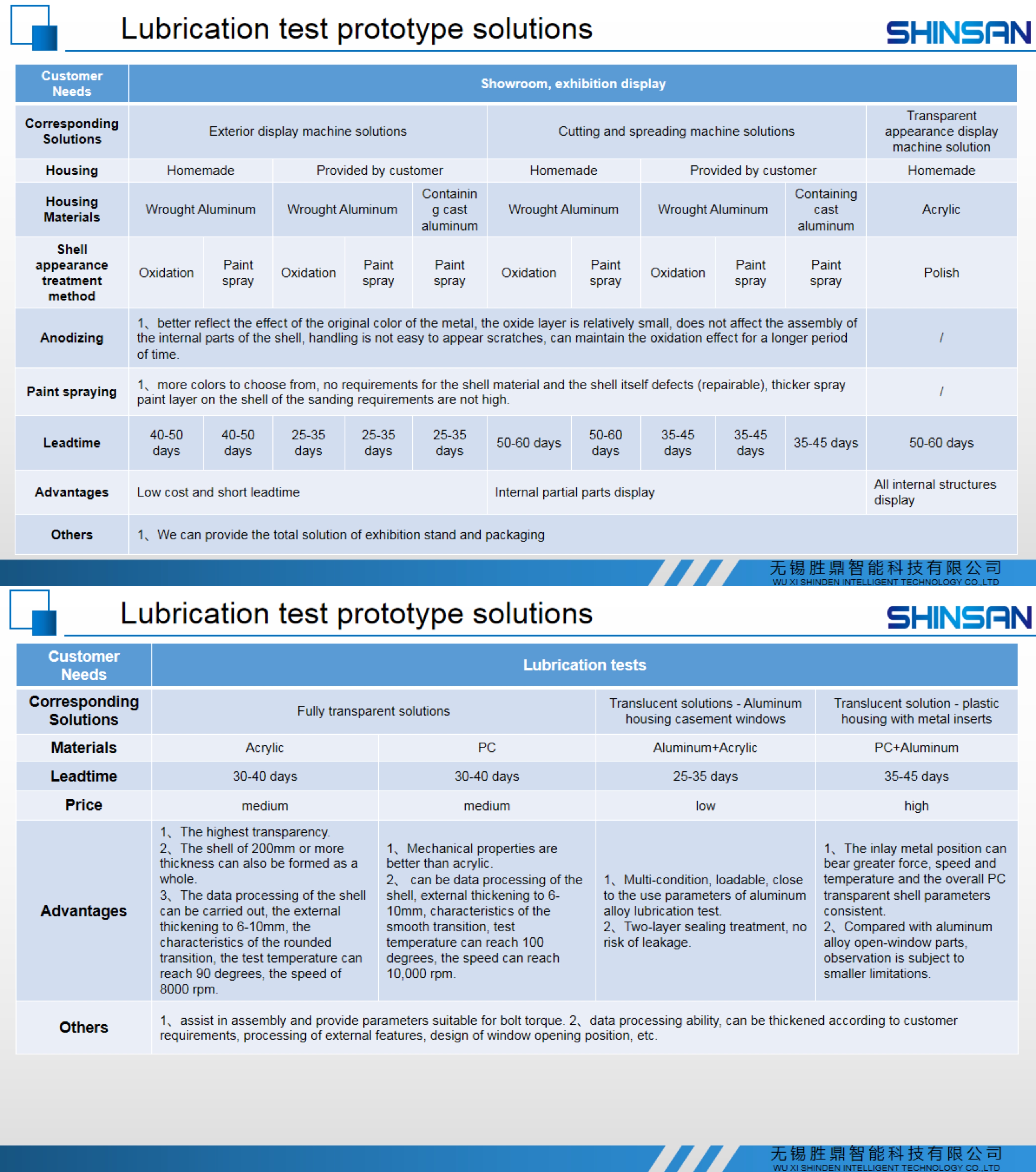

The clutch housing is located in the flywheel housing between the engine and the gearbox. The clutch assembly is fixed on the rear plane of the flywheel with screws. The output shaft of the clutch is the input shaft of the gearbox. During the driving of the car, the driver can press or release the clutch pedal as needed, so that the engine and the gearbox are temporarily separated and gradually engaged to cut off or transmit the power input from the engine to the transmission. The clutch is a common part in mechanical transmission, which can detach or engage the transmission system at any time. The basic requirements are: the joint is stable, the separation is rapid and thorough; Easy to adjust and repair; Small profile size; Low quality; Good wear resistance and sufficient heat dissipation capacity; Easy to operate and labor-saving, commonly divided into two types of dental insert and friction. It can be manufactured by CNC engraving, sand casting, transparent acrylic(PMMA/PC) 3D Printing.

Aluminum alloy clutch shell is usually used in the mass production stage of metal high-pressure casting process, mold cost is high, manufacturing cycle is long, can not meet the trial production stage project development schedule and cost requirements. In the previous trial production stage, the company generally adopts the sand gravity casting process, which has low mold cost and short trial production cycle. However, for the thin-walled parts such as the clutch shell with large shape size and uneven wall thickness, the pouring system design is complicated, the modeling is difficult, and the process yield is low. In addition, due to the low sand mold temperature, the aluminum liquid in the pouring process has a large cooling range. In the thin-wall part, it is easy to produce insufficient pouring or cold insulation defects, and even if the riser is used in the thick part, its effect is relatively limited, and it is easy to produce shrinkage and loosening defects. However, the increase of pouring temperature will lead to high gas content of the melt, which is easy to produce defects such as shrinkage holes.

Established in 2010, Wuxi SHINDEN Modern Intelligent Technology Co.Ltd aims to become a first-class rapid manufacturing enterprise in China.

We are committed to helping companies' R&D and innovation by providing

Dimension: Based on clients' design drawing

View More

Video

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier